EQUIPMENT

The creation of Yoshikawa products is backed by the latest technology and stringent quality control.

Yoshikawa products are manufactured using advanced production technologies and a reliable quality control system. Meticulously designed Circle Feeders are completed on a production line with the use of precision machinery, technological expertise, and experienced craftsmanship.

Prior to 1994, primary processing such as cutting, rolling and pressing was usually outsourced. In an effort to realize complete in-house production, a laser cutting machine, a vertical bending roller and a press brake were introduced in 1994. The introduction of this equipment enabled integrated manufacturing from material processing to the finished product, creating a more flexible production system.

| Equipment | Manufacturer / Model | No. of Units |

|---|---|---|

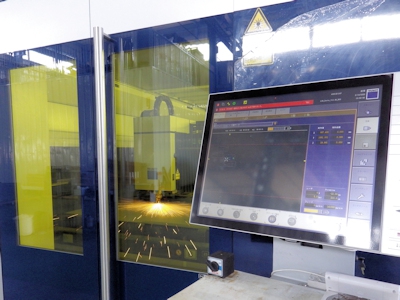

| Laser cutting machine | TRUMPF TruLaser 3030 | 1 Units |

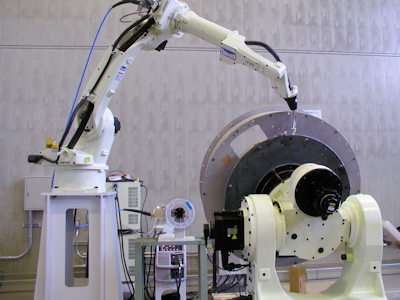

| Welding Robots | DAIHEN NB4L2 | 1 Units |

| Press brake | AMADA RG-80 | 1 Units |

| Bending roller | Matsumoto Seisakusho MBR-Oht | 1 Units |

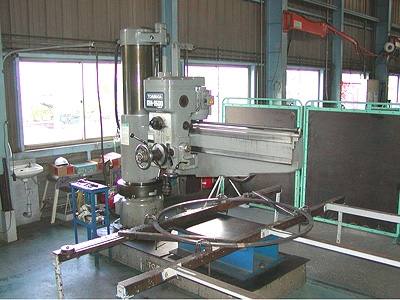

| Radial drill | TOMINAGA RH-1500 | 1 Units |

| CNC lathe | Okuma LB4000EX | 1 Units |

| Wire electric discharge machine | Mitsubishi Electric DIAX BA24 | 1 Units |

| 2-axis positioner | Matsumoto Kikai | 4 Units |

| 3-axis positioner | LINE WORKS SK3000CL | 1 Units |

| 3-axis positioner | LINE WORKS NSK1000CL | 2 Units |

| Beveling machine | Hataly | 1 Units |

| Overhead traveling crane | 2.8 t | 22 Units |

| Steel sheet stocker | KITAGAWA SEIKi KSP | 3 Units |

| Varieties of welders | ARC welder / MAG welder / TIG welder | |

| Pickling tank |

Equipment photos

-

Laser cutting machine -

Laser cutting machine -

Welding Robots -

Press brake -

Bending roller -

Radial drill -

Lathe -

CNC lathe -

Wire electric discharge machine -

2-axis positioner -

3-axis positioner -

Beveling machine -

Overhead traveling crane -

Steel sheet stocker

-

Corporate Profile

Corporate Data (including date of establishment and capital)

-

Management philosophy

The philosophy that represents the backbone of Yoshikawa's corporate management.

-

President's Message

Message from the President

-

Access

Yoshikawa access and area map

-

Organizational Chart

Organizational chart of Yoshikawa.

-

Corporate History

The development of Yoshikawa since its foundation

-

Compliance

Yoshikawa faithfully complies with all legal requirements and ethical practices, and contributes to society.

-

Environmental Principles and Environmental Policy

Yoshikawa Corporation works to reduce environmental impact based on its management philosophy.

-

Equipment

The creation of Yoshikawa products is backed by the latest technology and stringent quality control.

-

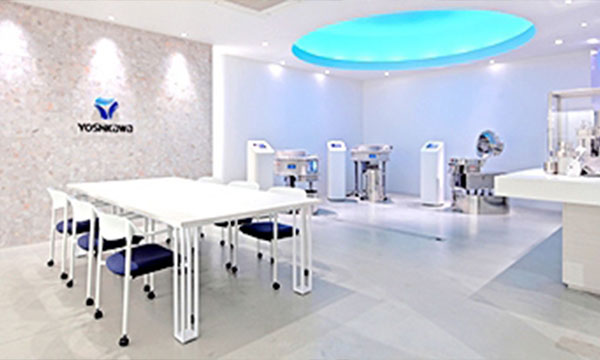

YOSHIKAWA Showroom

Opened a showroom with a Circle Feeder installed.

-

Yoshikawa Products Sales Trends

Market share of Yoshikawa products, industrial fields in which they are playing an active role, etc.

-

Agents

Introduction to our overseas agents