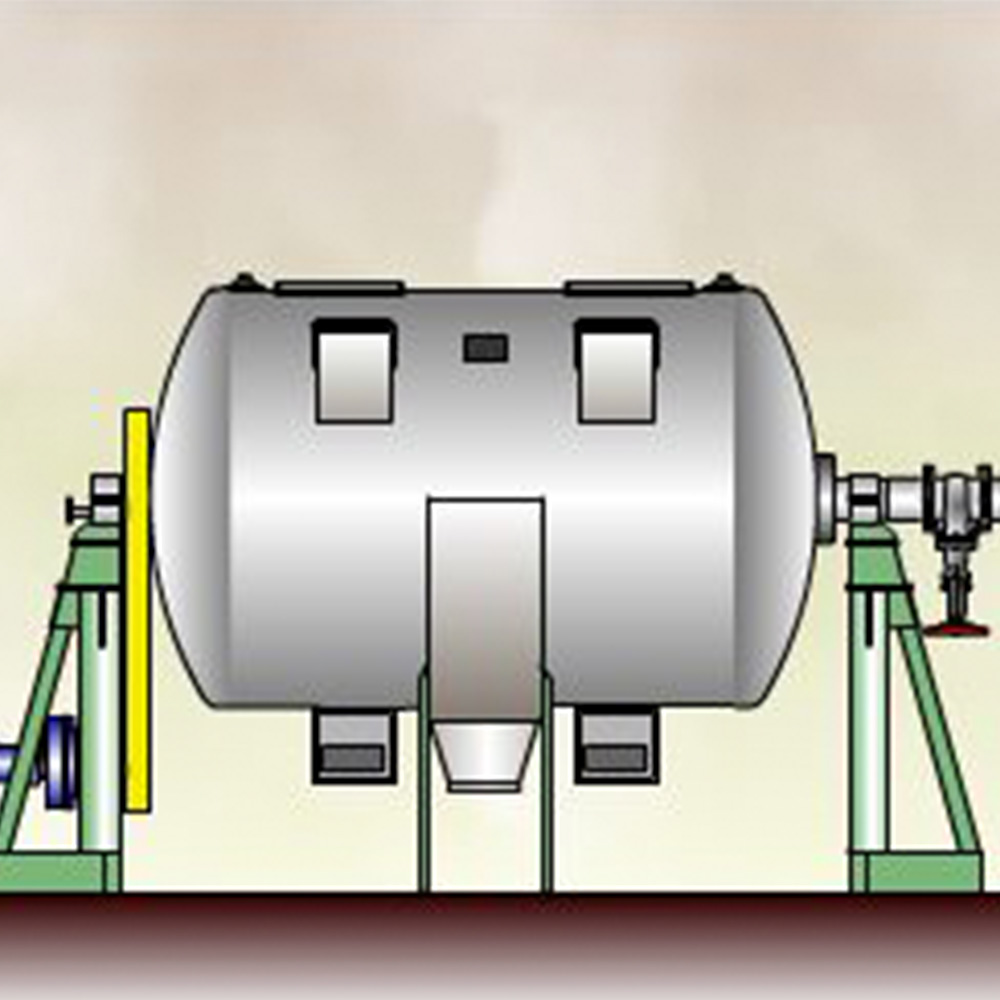

Stable feeding is key for a dissolution unit.

- The unique initial dissolution system enables thorough dissolution.

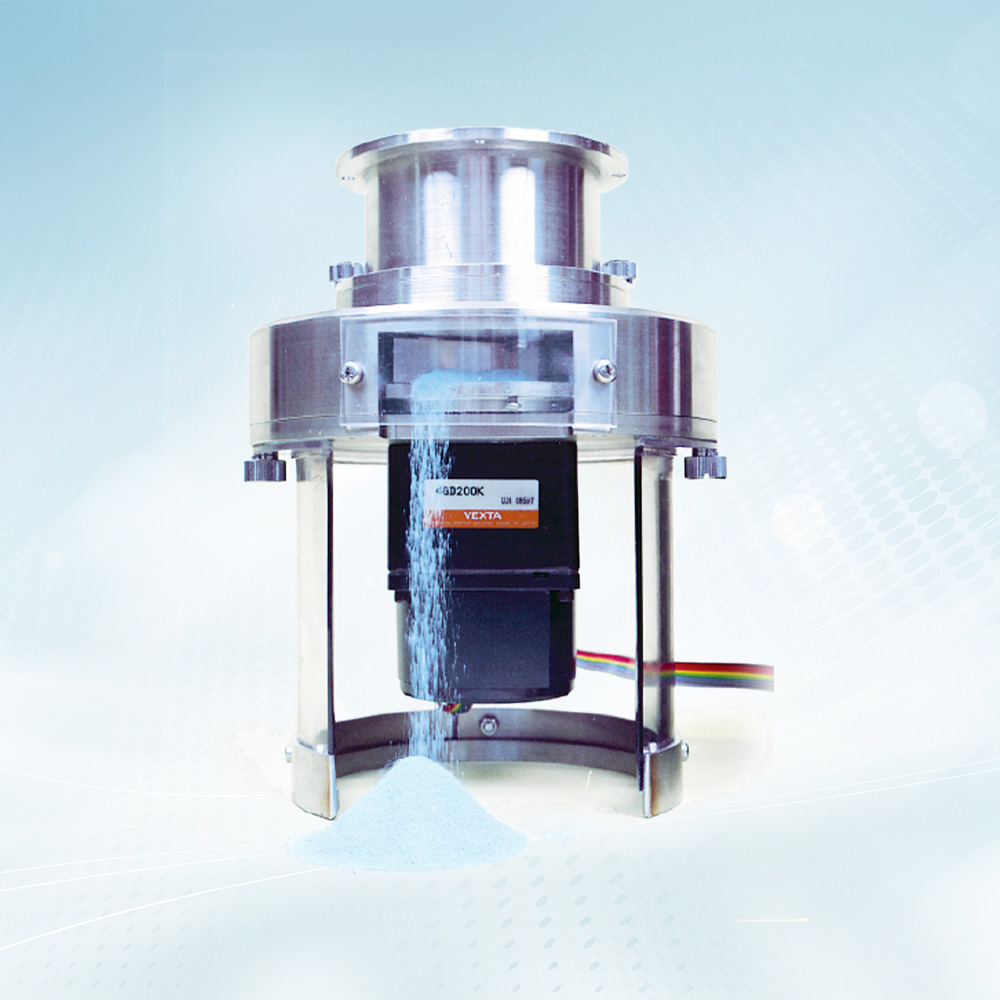

- The use of a condensation prevention chute allows stable feeding.

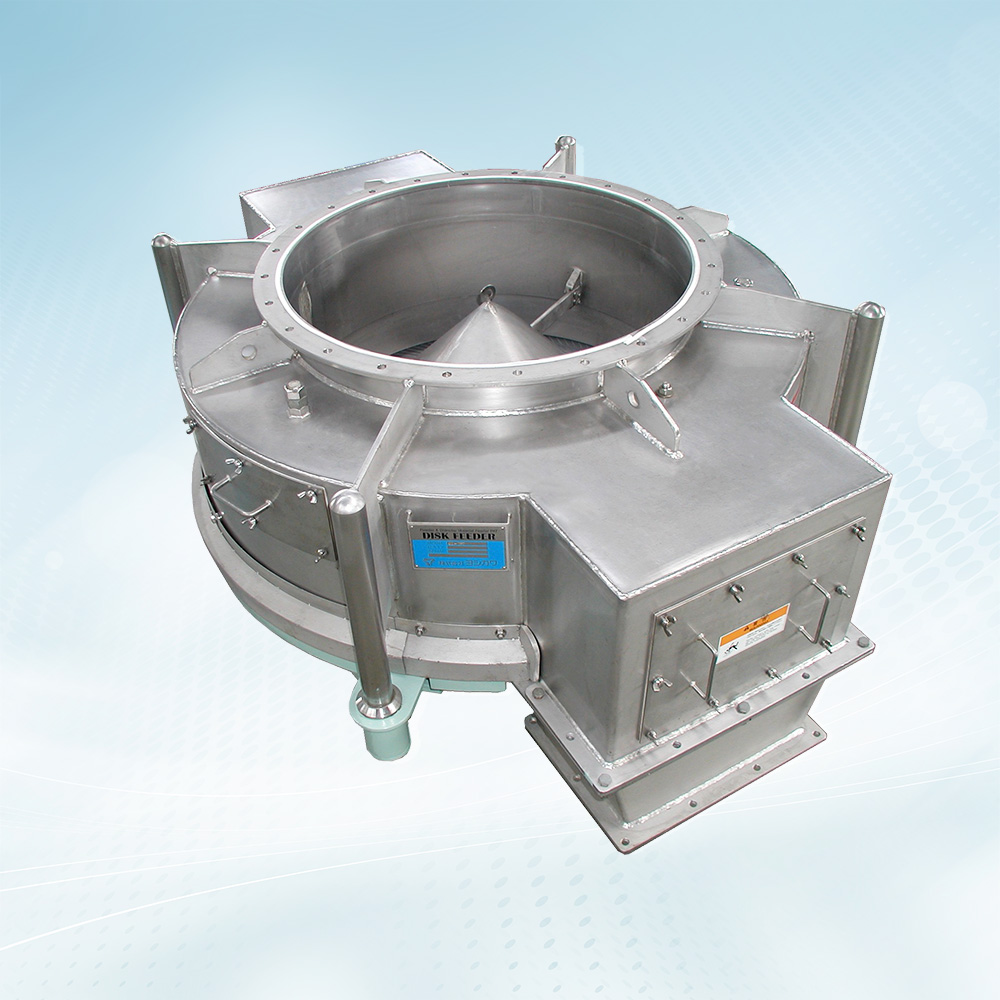

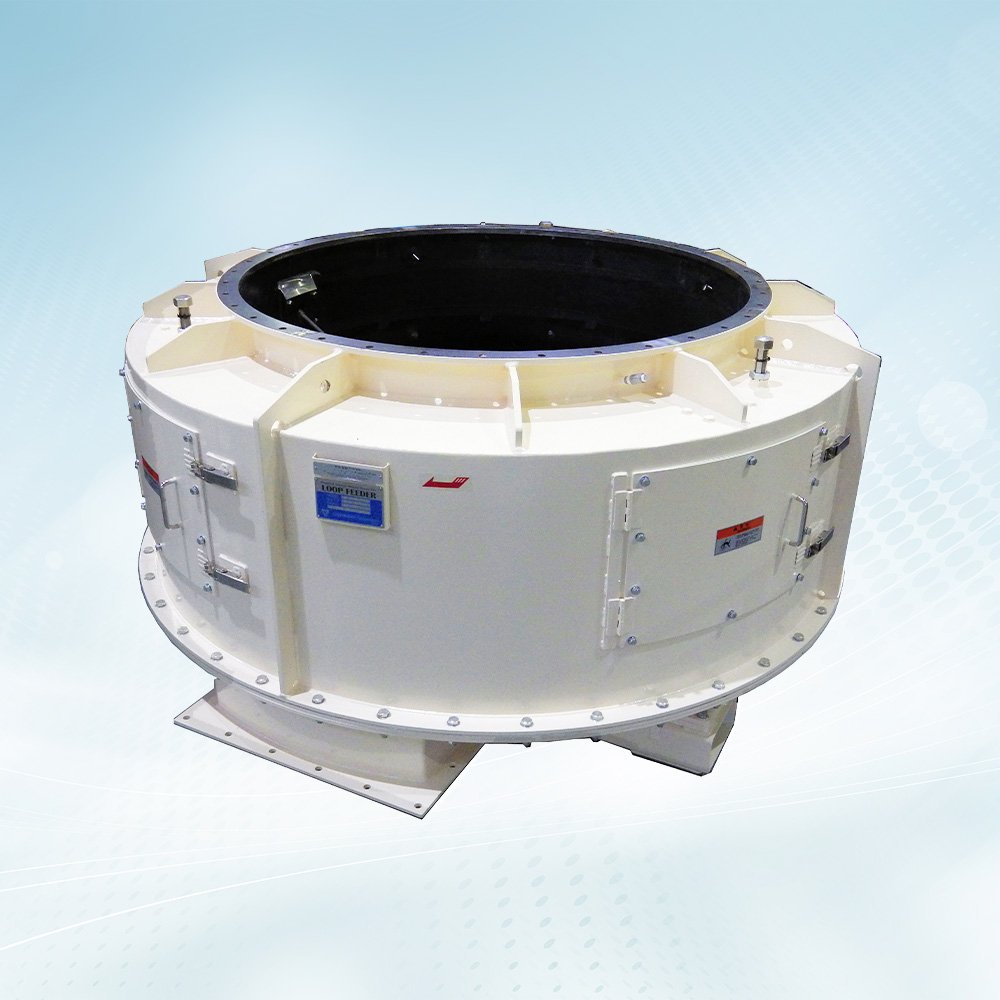

N Type: Standard specifications

- Dissolves the material fed at a fixed rate, in water fed through a constant flow-rate valve.

- Limiting functions to those needed means reduced prices.

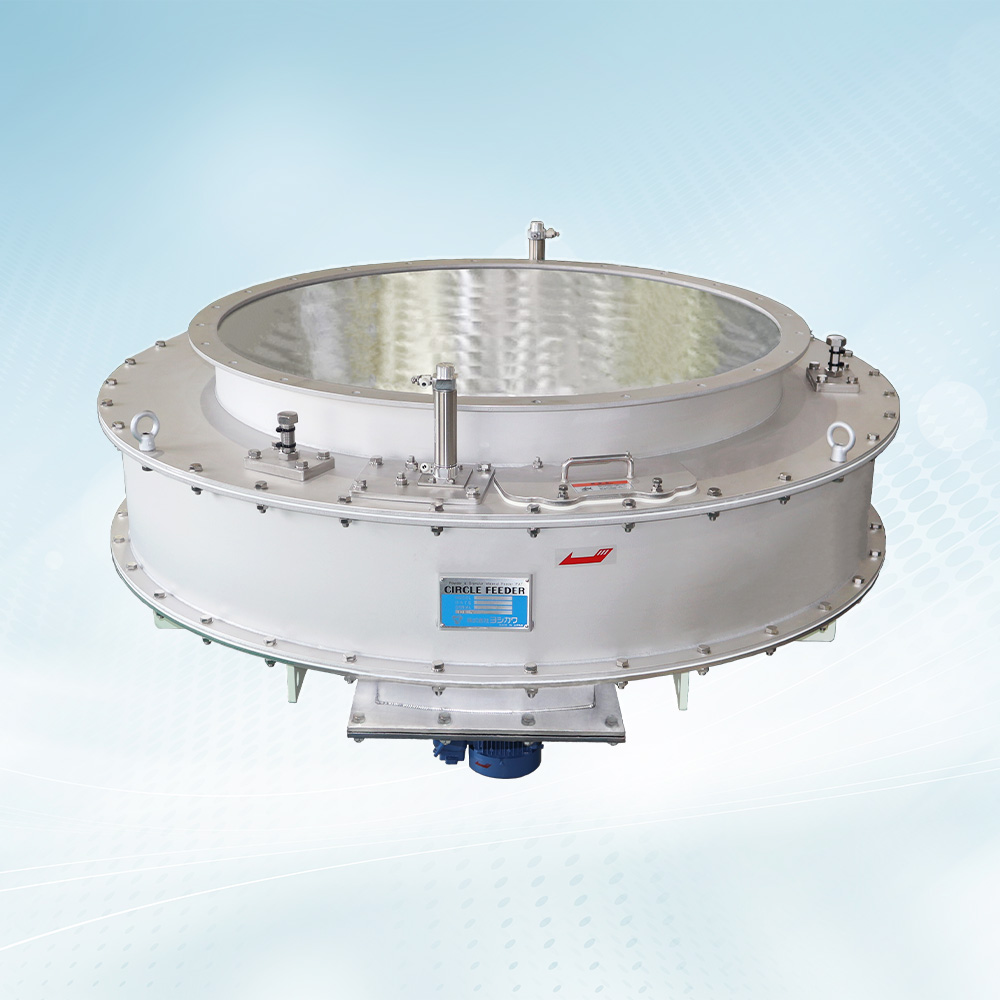

- A mounted Circle Feeder enables stable, bridge-free feeding.

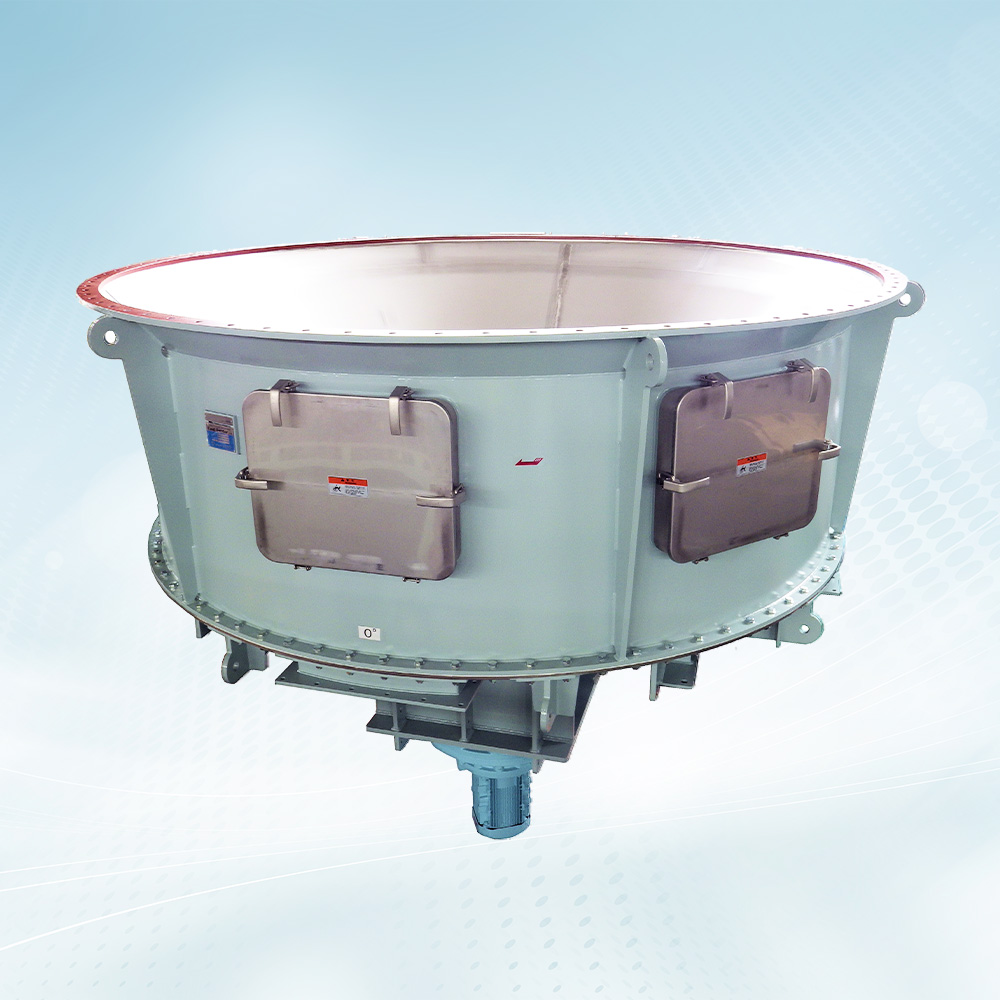

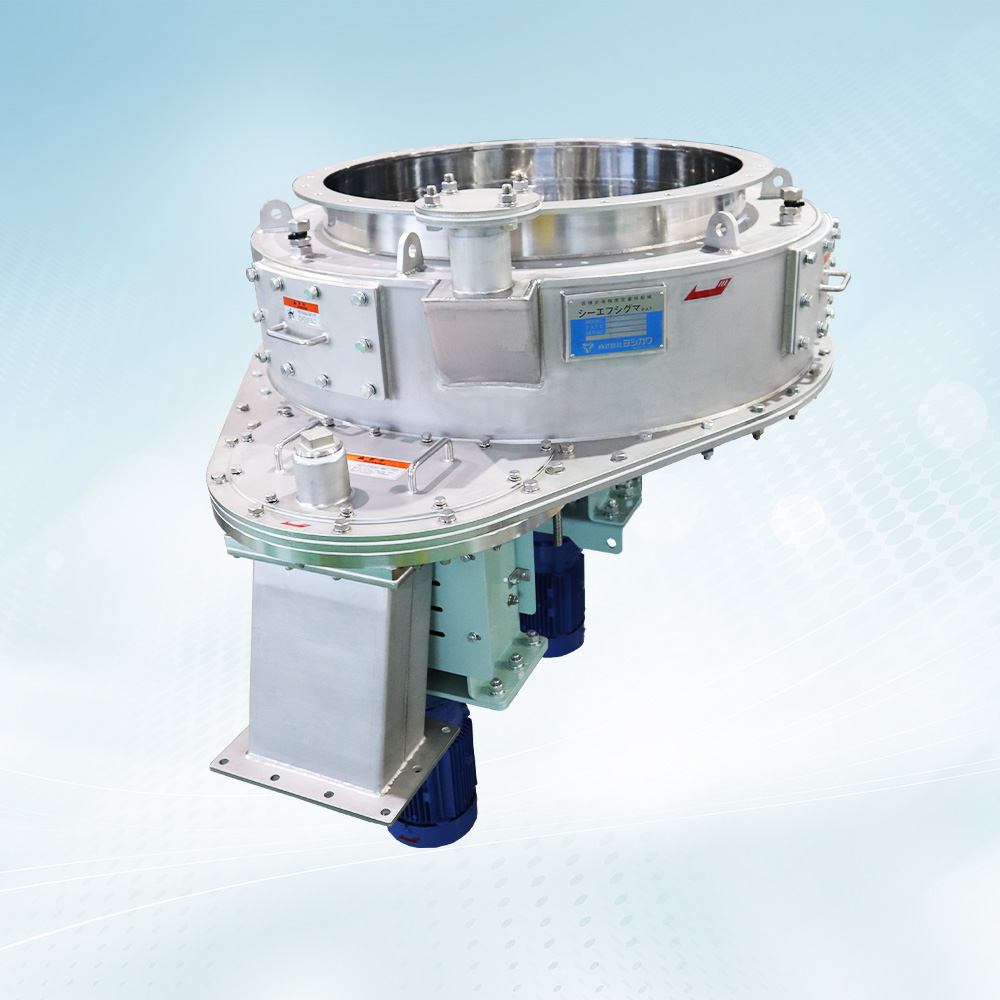

P Type: High-performance specifications

- Monitors water supply to control the powder feed-rate in proportion to the water flow-rate (proportional feed-rate control).

- A touch panel screen allows the monitoring of dissolved volume with a simple operation.

- The mounted Circle Feeder enables stable, bridge-free feeding.